Prototyping

Prototype is an essential for new product development, as one-stop service provider, during new products development and manufacturing, for most products, we always help to make prototype before mold making and mass production, to quickly test and verify the design, appearance, structure and function. By creating a prototype, designers can identify potential issues, make necessary adjustments, and ultimately save time and money in the long run.

Faisun Prototyping Services

> MOQ: small to 1 piece, no MOQ limit.

> Commonly used materials: PMMA, PC, ABS, PP, NYLON, Aluminum, and Brass, Somos, Taurus.

> Technology: SLA, SLS, CNC machining, vacuum casting.

> Lead time: as fast as 3 to 10 working days.

> Tolerance between 0.01mm – 0.1mm.

Prototype processes

Including CNC, vacuum casting, metal sheet and quick mold

Prototype processing material

Plastic

|

ABS |

PC |

PE |

POM |

PP |

Arcylic |

Nylon |

Silicone |

Rubber |

- |

Metal

|

Aluminum |

Zinc |

Magnesium alloy |

Titanium alloy |

Stainless steel |

Metal sheet |

Steel |

Copper |

Iron |

- |

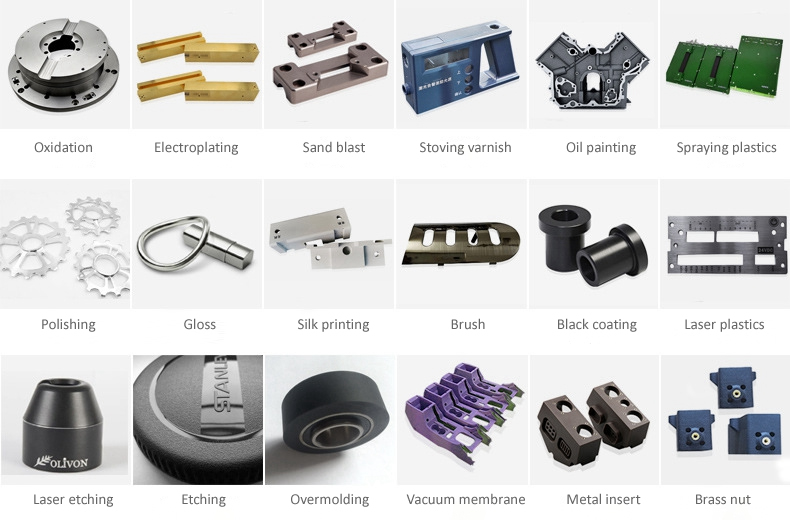

Prototype processing finishing