Design & Development

Bring your smart design to real product in life by Faisun’s talented and experienced team

Faisun has a unique know-how: the tailor-made developing and manufacturing solutions of silicone, plastic and metal molds and molding parts. We understand all your constraints and provide perfectly adapted solutions!

As one-stop turneky service provider and manufacturer, our supports bridge the gap between design, engineering and manufacturing (make prototype, build mold and set-up mass production, assembly and shipment), as well as lots of professional supports at middle (including drawing refine, mechanical engineering, reversed engineering, material suggestion, problem solving, production solution providing, packaging, packing/semi-assembly/final assembly...etc, the whole processes of new product development and manufacturing).

01 Product design

Faisun’s engineering team are familiar with software UG, PRO-E, Solidworks, CATIA and PS, after study client’s rough sketch/idea, brief description and budget, our team could help to create 2D & 3D drawing that are both feasible for production and cost-effective, things are conducted under Non-Disclosure Agreement.

02 Project analysis

Faisun’s experienced team fully study and analyze the project according to client provided information/drawing/sample, give feedback/suggestions (analyze drawing is feasible for production or not, if it’s high cost to produce current structure or not, if yes, how to refine the drawing or use alternative material/process/finishing to reduce cost, advise suitable material...etc) then quote in different options (make simple sample for test firstly then evaluate the cost if necessary).

03 Engineering

Faisun’s high skilled engineering team has over 15 years first site experience on new product development and manufacturing with strong engineering capability, especially mechnical engineering capability, including modify drawing, reverse engineering, analyze drawing, solve problem...etc after a comprehensive understanding of the project details, specifications, functions, usage environment, marketing...etc, which could ensure the product are both feasible for tooling building and production with cost-effective.

04 Prototyping

Before mass production, we help customers to make prototypes/samples through CNC machining, 3D printing and urethane (vacuum) casting solutions to further verify the design, test the prototype (functional test, shape/appearance test, color test...etc), as well as reduce potential mechanical design risks at a preliminary stage, which could shorten the whole leadtime and ensure whole product successfully develop.

05 Mold

Faisun provides DFM (Design For Manufacturing), MFA (Mold Flow Analysis), MFMA (Design Failure Mode Analysis) and mold design drawing per specific project and client requirement.

Our molds are made based on several factors including part geometry, molding material properties, the specific molding process, and product life cycle estimates, and the mold manufacturing process includes the use of advanced features like exchangeable cores, hot runner systems, and multi-cavity configurations.

06 Production

Faisun specializes in contract manufacturing of plastic, silicone and metal molds and their finished products, adhering to ISO9001, TS16949 quality management systems.

Faisun manufacturing service including pilot-run, small volume production and large volume production, as well as secondary surface finishing, semi-assembly, fully assembly and packing.

During project development and manufacturing, from EVT (Engineering Verification Test), DVT (Design Verification Test), PVT (Production Verification Test) to MP( Mass Production), Faisun work closely with client’s team, keep fully communication and provide lots of extra supports to ensure the project is successfully devleop in cost effective manner as below:

Cost reduction

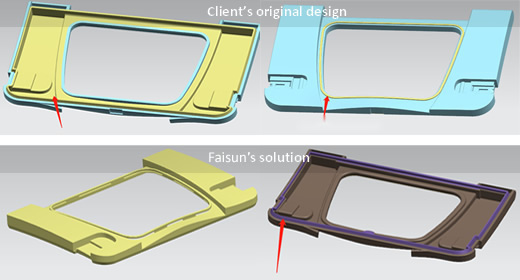

Original client design: Blue area is hard plastic and yellow area is soft plastic, they’re processed by dual-colors injection, part’s unit price is high.

After fully study the whole product’s function, usage environment and this’s part function in the whole product and the purpose to have 2 colors for this part, Faisun’s team drives cost reductions on both a component manufacturing and assembly level, then share our idea to client to help them save 70% mold cost and 120% unit price by using alternative material and other manufacturing process, which could reach the same function and purpose.

Comply with local regulations

Faisun has extensive experience in the development and production of Toys, Kids & Baby products. Many of the silicone baby products we produced are sold in major supermarkets around the world such as Target, Costco, Macy's, Buybuybaby, Amazon, Walmart, Toyrus...etc and exported to various countries, also have a wide understanding of chemical and physical safety test of Toys, Kids & Baby products in various countries.

After fully understanding the customer's requirements and target selling market, while ensuring 100% food-grade contact safety, non-toxic, BPA free, PVC free and competitive price, based on our experience, sharing client our idea of product structure refinement, recommending customer product materials, providing production process and pattern printing processes solutions, thus passing the physical tension test - 90N, the printing durability passed the cross cutting test, fingernail clips test, 5 kinds of liquid test (sweat, salt water, oil, acetic acid and saliva), dishwasher test.

Manufacturing reliability

Faisun’s goal is to make product development and production easier and lower cost, with our professional support by suggesting materials, refining interior structure, improving product reliability, reducing potential for failure, and lower the return risk to our customers. We work in close cooperation with customers on troubleshooting problematic components or assemblies and provide input from both our team and upstream suppliers in order to de-risk customer designs.

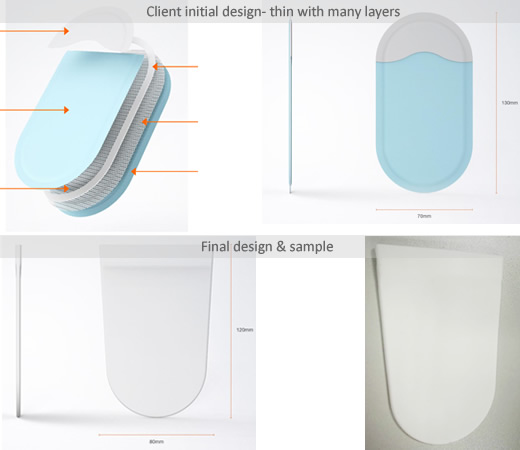

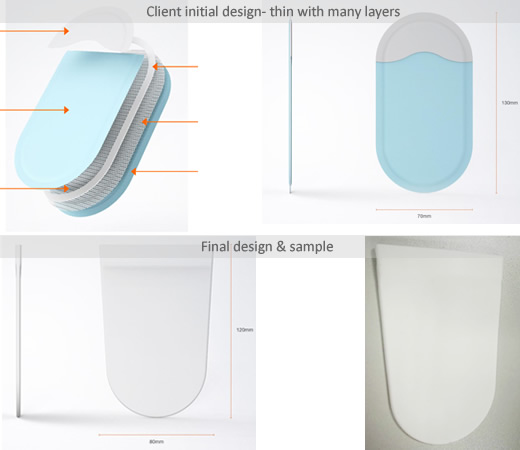

Client's initial design sketch is thin wall with many larers, the structure is complex which is difficult to produce with high cost. After fully understanding the customer's product function and usage environment, we put forward our structural suggestions, simplify the structure and help customers refine the drawings free of charge, suggest materials, make samples to customers for testing, and run 3 validation test runs EVT, DVT, PVT (Engineering Verification Test, Design Verification Test and Production Verification Test) before mass production, these ensure smooth product development and manufacturing of the whole product.

Design & Engineering Optimization

Faisun has extensive design for manufacturing experience we bring to bear on new product introduction projects, and new OEM products introduction projects working with customers to improve all aspects of the design, from reliability to repeatability to cost-effectiveness.

Based on client’s design, some parts are undercut which are not feasible for production, some parts are too thick that will cause high cost, Faisun’s design and engineering supports as below to make it feasible for production with cost effective manner.

- Drawing refine (adding fillet/draft angles from production viewpoint).

- Finalize structure (split or combine some of the parts and complete interior structure to lower the production cost).

- Advise material that suitable for outdoor use.

- Advise production process to reach high tolerance requirement.

- Make appearance and functional prototype for test.

- Design for mold and manufacturing.