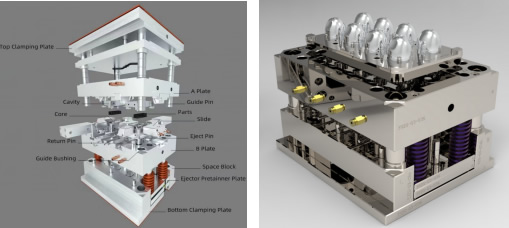

Molds

Molds are often used in high-volume and high precision products, a good mold is the fundation of good product, which could guarantee high cyclelife and high dimensional accuracy.

Faisun’s skilled and experienced design and engineering team with 15+ years industrial technology background and are consistently stay up to date with new technology and software like UG, Solidworks, Pro-ENGINEER, Auto CAD, CATIA, Moldflow, MasterCAM to provide customers professional but low-cost technical support from rough sketch to part design, mold-flow analysis, DFM analysis, mold design, mold manufacturing, till final products finishing.

We’re dedicated to meeting quality standards in the following industries: Automotive, Applicance, Bath, Outdoor Living, Kitchenware, Smart Home, Healty & Beauty Care, Toys, Kids & Baby, Electronics, Pet Supplies, Sports, and many others, whether you aim to reduce material cost, enhance its function or lower production cost...etc, all demands will be addressed.

Faisun molds expertise:

> Plastic injection mold

> Insert mold

> Over mold

> Double-shot injection mold

> Metal die casting mold

> Extrusion mold

> Silicone compression mold

> Silicone injection mold

Faisun could design & make the mold per customers' product designs, 2D/3D models or drawings with specifications, drawings in STEP/STP, IGS, X-T format are available for us. Our design capabilities include:

Reverse Engineering

Study & analyze your product and design files carefully and create the perfect mold, do pre-deformation analysis for large products.

DFM Analysis

To ensure the best performance of the mold, our engineers analyze in-depth for gate, parting line, injector pin, slider...etc and potential issues as well as provide professional solutions.

Mold flow analysis

Through the simulation of virtual molding, we can enhance the mold design before creating the mold, reducing delays and additional costs in the long run.

Full 2D & 3D mould design

We can make 3D output according to the customer's samples data, and make 2D mold layout drawings and 3D mold design drawings.

Mold of bluetooth speaker